That makes your work significantly faster – you can conduct more measurements in the same time if necessary.

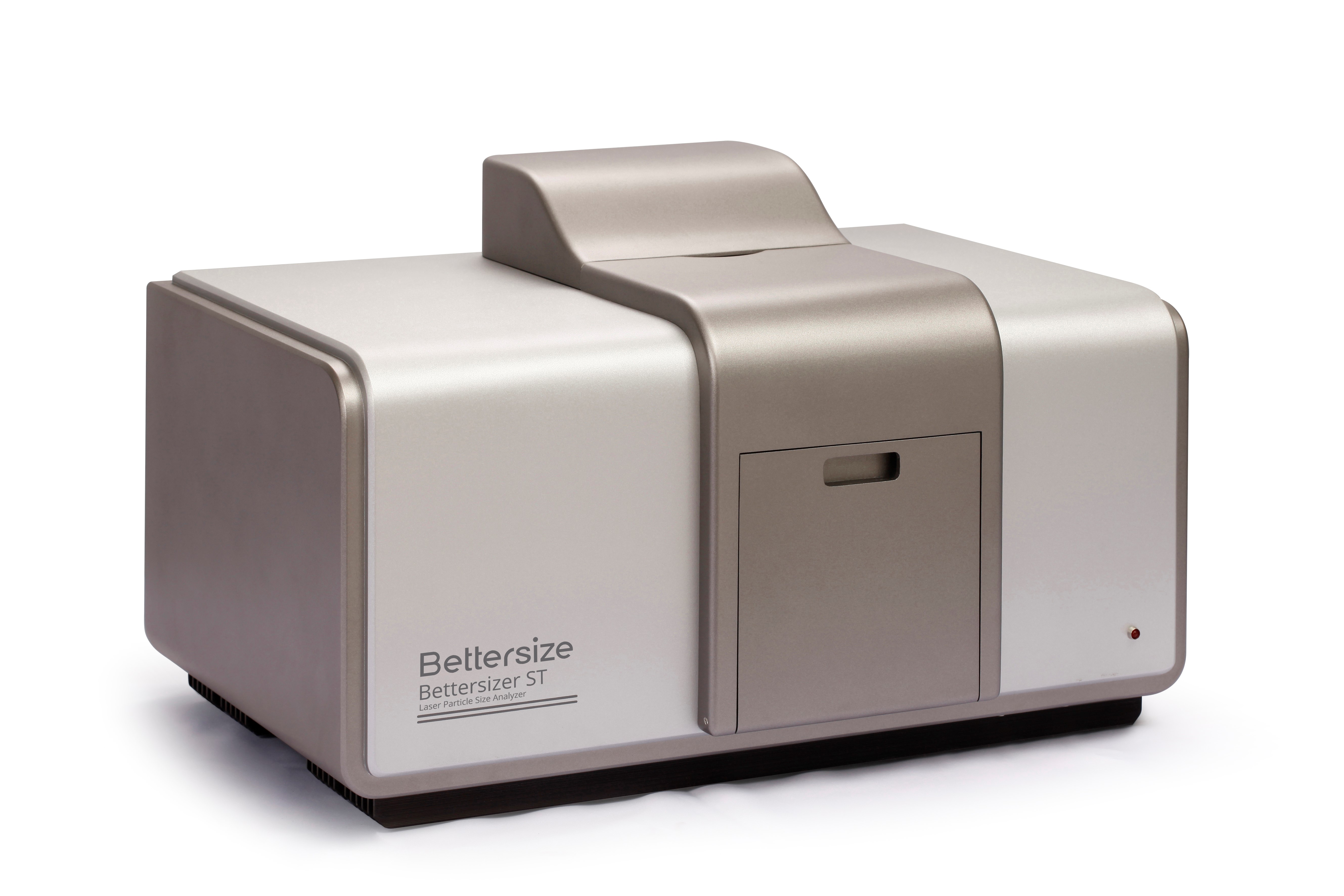

Therefore it records the entire measuring range with only one scan. The ANALYSETTE 22 NeXT operates with only one laser and does not need an additional light source even for backward scattering.

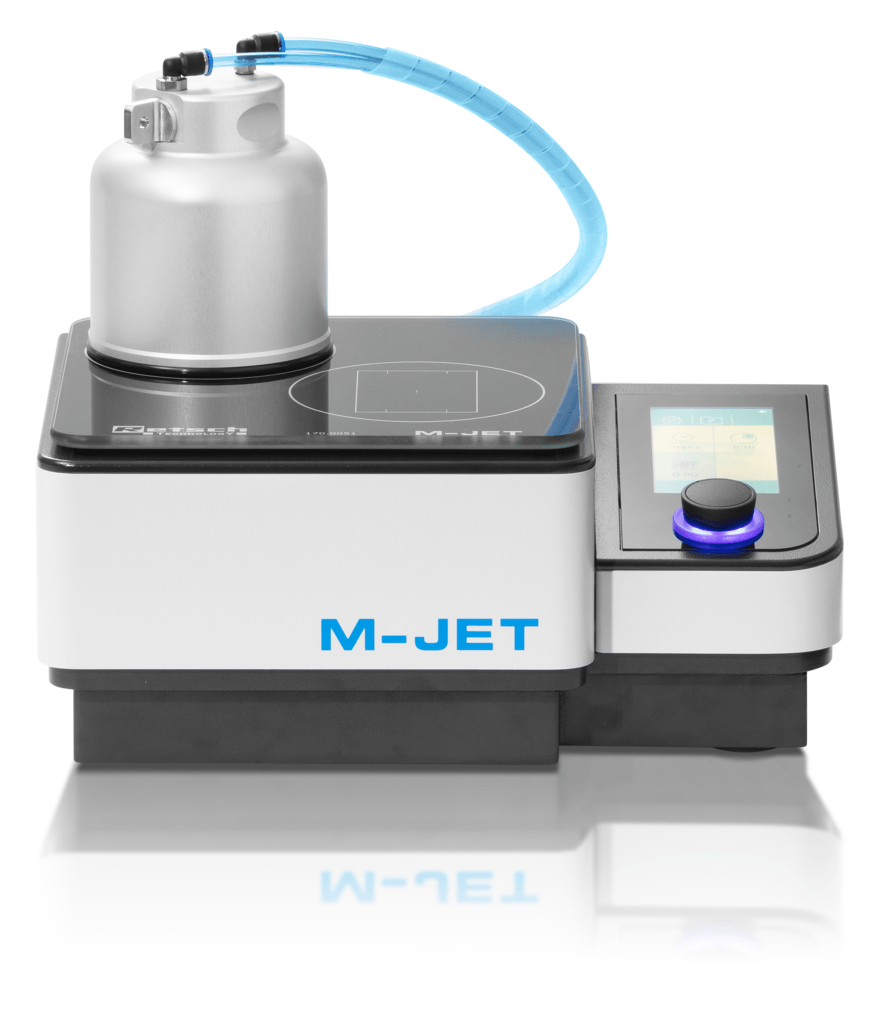

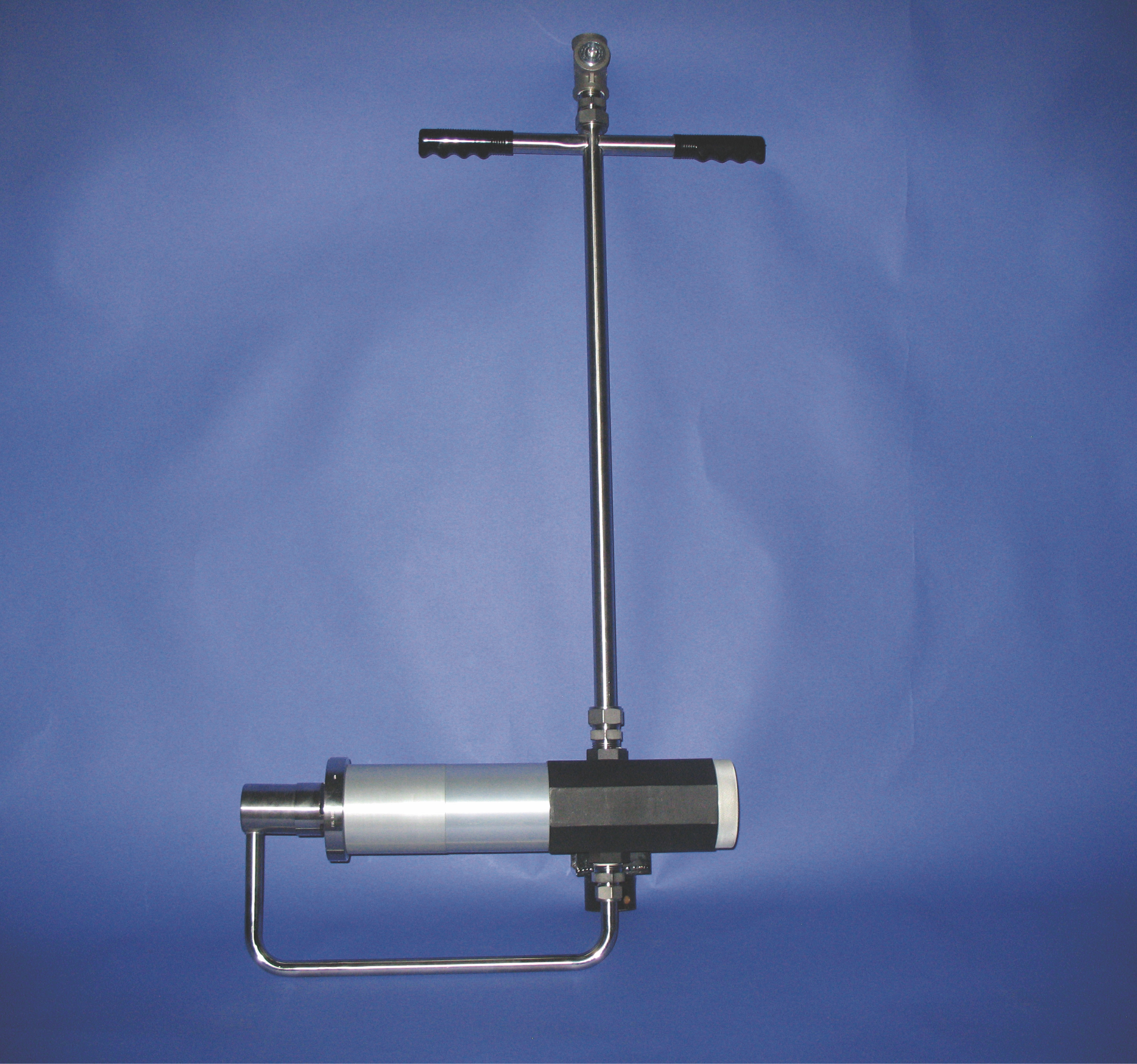

Recording also of very wide scattering angles by intelligent measuring cell design.Highly precise recording of the light intensities by state-of-the-art 16 bit converter technology.Quick and simultaneous recording of all scattering data.Only one light source: simple, robust, reliable.The design is compact with as few components as possible and has no moving parts – low wear and practically maintenance-free. Your advantage: No additional optical elements are necessary between the measuring cell and detector. The current generation ANALYSETTE 22 NeXT operates like every FRITSCH Laser Particle Sizer to date with the Reverse Fourier design invented by FRITSCH which has established itself by now as a general standard. Get all the decisive advantages with the model that meets your requirements: especially easy operation and cleaning, short analysis times, reliably reproducible results and the recording of additional parameters such as temperature and pH value during wet dispersion. Of course, you can also save and print out a report customised to your needs. The complete evaluation of the particle size analysis takes place automatically with clearly organised results visible directly on the screen. The measuring time is for most measurements less than a minute – including a reliably residue-free cleaning. The intelligently revised measurement design makes the ANALYSETTE 22 NeXT especially compact and space saving. The completely revised ANALYSETTE 22 NeXT Nano with an extra wide measuring range of 0.01 – 3800 μm for maximum precision and sensitivity for smallest particles with an additional detector system. This means that the technology is suitable for a wide range of materials, whether fragile or abrasive, or difficult to disperse.Automatic particle size analysis down to the nano-range: unbeatably simple and affordable A range of sampling optionsĪs no two applications are the same, a range of sampling options are available to ensure optimal dispersion / wear protection is addressed. It is easy to configure the system for ‘one click’ measurement. Easy operation of softwareĪll functions you would expect in a laser diffraction laboratory instrument are available in the software, in an easy to use interface. Where cleaning is required, this can be done with no complex realignment of the system optics. The unique cell clean system ensures maximum up time between maintenance. This ensures stability of measurement over a wide range of temperature and humidity. The unique concept of building the system inside an optical bench gives the system the strongest and most rugged configuration of any instrument available. Problems or unforeseen events are also rapidly detected. Real time monitoring optimizes the production line by increasing productivity, optimizing quality and reducing energy costs. There is no loss of product, as sampled material is automatically returned to the process.

Automatic sampling from production process decreases the human cost.

0 kommentar(er)

0 kommentar(er)